|

|

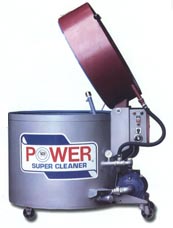

An optimal cleaning of oily components such as engine parts, machining parts, plastic parts, and wooden parts can be achieved by the combination of heat, pressure and chemical. The machine can easily be paid off by itself in a very short period of time through time and labor saving. It provides the solution in cleaning of the oily and dirt contamination of components in assembly industry, especially the engine assembly.

The panel control features : * Timer ; * Heater lamp indicators ; * Temp control lamp indicator ; * Temperature control setting ; * Switches, Push button, for start and stop the operation. Feature are : * Time and labor saving due to the automatic operation of the machine itself ; * Timer control for easily setting the duration of cleaning operation ; * Only 5-10 min. cleaning time, depending on how oily workpiece is ; * Very easy and convenient to operate by an unskilled labor with simple operating instructions to follow ; * Environmental-friendly and no health hazard because cleaning chemical is mild alkaline and small amount is being used and biodegradable ; * Waterproof-sealed for electrical components to provide no electrical leakage ; * Safety, operation can not start when top cover is not properly locked by latch ; * Low cleaning solution by employing a mixture of water and small amount of chemical, mild alkalinem, approx. 2% ; * Easy access for loading and unloading workpieces with basket ; * Light indicators to inform the status of the setting such as the water level and temperature setting ; * Heating and spray-injecting systems effectively provide means of assisting in oily desolving and scrubbling actions during cleaning operation. It can easily be removed for regular cleaning ; * Simple electrical wiring for easy troubleshooting ; * Quality material and reliable components ; * Totally enclosed system, so workshop stays tidy and dry ; * Equipped with trolley for easily and conveniently moving around the garage, workshop, and / or factory floor ; Your Places of Usage Various facilities which employ Power Super-Cleaner for cleaning their oily components and parts such as : Garages, Injection Pump Test Center, Brake Service Shops, Mass-Transit Service Centers, Machining Workshops, Military Equipment Service Center, Steel Mills, Dockyards, Refineries, Electroplating, Painting Workshop, Foundry Workshop, and etc. |

Typical cleaning applications are :

Typical cleaning applications are :

| MODEL | P 80 | P 105 | P 120 |

| Outside Dia.,(mm.) | 950 | 1250 | 1400 |

| Width, (mm.) | 1200 | 1500 | 1620 |

| Height, (mm.) | 1100 | 1200 | 1300 |

| Basket Dia. (mm.) | 800 | 1050 | 1200 |

| Basket Max load, (kgs.) | 300 | 400 | 500 |

| Solution capacity, (litres.) | 150 | 200 | 300 |

| Working Pressure (bars) | 4 | 4 | 4 |

| Moter (kw.) | 2.25 | 2.25 | 2.25 |

| Heater (kw.) | 9 | 9 | 18 |

| Supplied voltage, (volts)* | 380/220 | 380/220 | 380/220 |

| Phases | 3/single | 3 | 3 |

| Frequency, (Hz.) | 50/60 | 50/60 | 50/60 |

| MODEL | PSQ 80 | PSQ 105 | PSQ 120 |

| Outside Dia.,(mm.) | - | 1400 | 1650 |

| Width, (mm.) | - | 1700 | 1950 |

| Height, (mm.) | - | 1400 | 1700 |

| Basket Dia. (mm.) | - | 1050 | 1200 |

| Basket Max load, (kgs.) | - | 500 | 500 |

| Solution capacity, (litres.) | - | 400 | 600 |

| Working Pressure (bars) | - | 4 | 4 |

| Moter (kw.) | - | 4 | 4 |

| Heater (kw.) | - | 18 | 18 |

| Supplied voltage, (volts)* | - | 380/220 | 380/220 |

| Phases | - | 3 | 3 |

| Frequency, (Hz.) | - | 50/60 | 50/60 |

|

BJ MOTOR PART, CO.LTD. 383/141-2 Vorajak Centre ,Chakapatdipong Rd. Pomprap Bangkok 10100 Thailand. Tel. (662-224-5978), (662-224-6580-2), (662-225-7237), (662-621-7513-4) Fax. (662-225-7238), (662-621-7514) |